REC Announcements

The current news can be retrieved from the navigation bar by clicking on the News button.

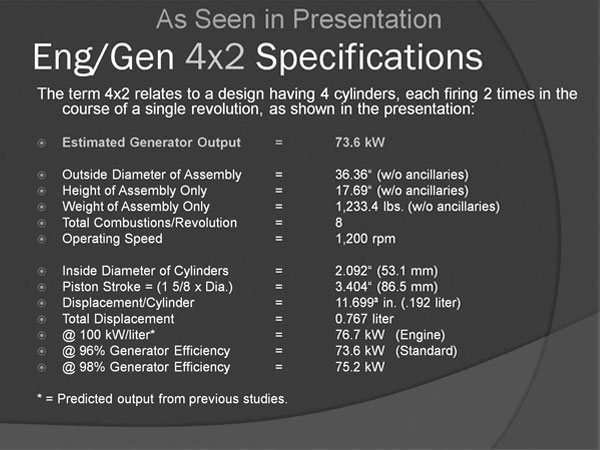

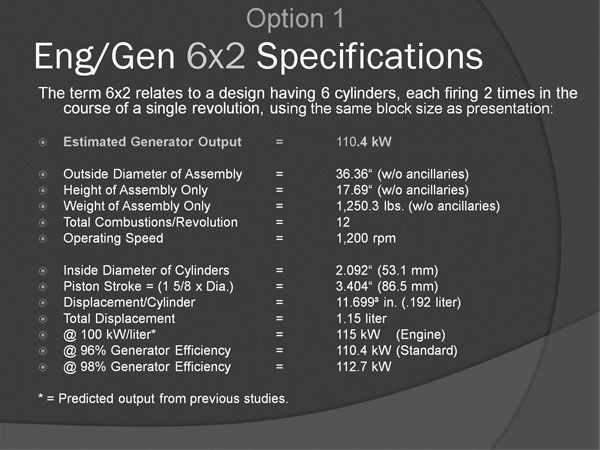

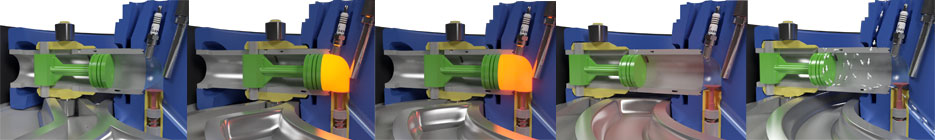

The base Engine/Generator depicted in this presentation was designed for use with gasoline or diesel fuels. It does not reflect the lastest design modifications or improvements incorporated in the current, patented Eng/Gen + Boost design. The Eng/Gen + Boost is designed for use with gaseous fuels, including RNG (renewable natural gas), hydrogen and propane.

To view the base Russell Engine/Generator video click on this LINK

Although the fuel type has changed, the basic design and configuration of the component parts have remained similar. There have been modifications to the combustion process, and the cooling system, which include the injection or injections of liquid water directly into the cylinders before, during and after the combustion event.

Please contact the Russell Energy Corporation directly with any questions or comments:

inquiry@russellenergy.com

comments@russellenergy.com

UPDATED WHITE PAPER

The Russell Energy Corporation White Paper has been updated and can be viewed by clicking on this link White Paper

_____________________________________________